In industrial piping techniques and machinery, components like 38 ball seat, 63 ball seat, and seventy six ball seat Participate in an integral job in making sure effectiveness, security, and trustworthiness. These smaller nonetheless vital sections are very important for retaining safe connections and optimizing fluid dynamics in different programs. Together with these, parts like bracket pipe seat and capping plug can also be indispensable in achieving exact technique performance. This article explores the functions and significance of those factors in detail.

What Are Ball Seats as well as their Purposes?

Ball seats are spherical parts meant to supply help and sealing within a system. They in many cases are Employed in ball valves together with other piping mechanisms to manage fluid movement. Each ball seat, such as the 38 ball seat, 63 ball seat, and seventy six ball seat, is tailor-made for unique diameters and force scores, ensuring a comfortable suit and successful Procedure.

By way of example, smaller sized units requiring precise Management could possibly use a 38 ball seat, when bigger industrial setups with increased movement premiums could reap the benefits of the durability and capability of a 76 ball seat. These components are manufactured from robust products like chrome steel or brass, providing resistance to corrosion and use in demanding environments.

The Job of Bracket Pipe Seats in Structural Integrity

A bracket pipe seat is crucial in supporting and stabilizing pipelines or conduits. These seats act as anchors, ensuring that pipes stay of their designated place, even beneath weighty masses or substantial-tension circumstances. By reducing movement and vibration, bracket pipe seats avoid harm to the process and add to its longevity. Capping Plug Their style and design is often custom made to suit certain pipe Proportions and operational demands.

Capping Plugs: Sealing and Defense

Capping plugs are adaptable elements utilized to seal the finishes of pipes or fittings briefly or forever. A capping plug makes sure that no contaminants enter the pipeline throughout upkeep or storage. In techniques requiring non permanent closures, these plugs supply a trusted solution without the require for complicated fittings. Their utility extends to both of those household and industrial applications, creating them a staple in piping techniques.

Picking out the Appropriate Factors for Your Process

When deciding upon factors like 38 ball seats, sixty three ball seats, or 76 63 Ball Seat ball seats, it’s important to evaluate the specific needs of your respective program, such as stress ratings, content compatibility, and operational temperature ranges. Equally, bracket pipe seats should be decided on dependant on the structural demands of the pipeline, even though capping plugs should really align Together with the pipe Proportions and wished-for sealing success.

Conclusion

Components like ball seats, bracket pipe seats, and capping plugs could appear minimal, but their influence on the functionality and safety of piping systems is immense. Whether or not it’s the precision of a 38 ball seat, the robustness of the seventy six ball seat, or the versatility of the capping plug, these components be certain that industrial and mechanical methods work smoothly and successfully. By being familiar with their roles and choosing the correct elements for your requirements, it is possible to improve the functionality and toughness of the programs.

Mason Gamble Then & Now!

Mason Gamble Then & Now! Michelle Pfeiffer Then & Now!

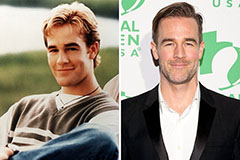

Michelle Pfeiffer Then & Now! James Van Der Beek Then & Now!

James Van Der Beek Then & Now! Morgan Fairchild Then & Now!

Morgan Fairchild Then & Now! The Olsen Twins Then & Now!

The Olsen Twins Then & Now!